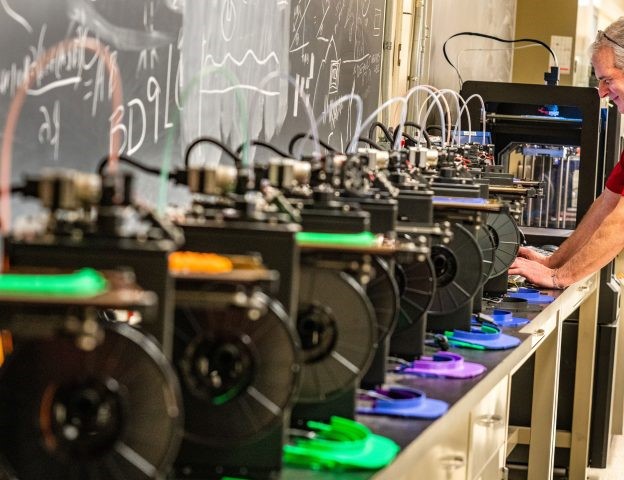

Brian Anderson ’14, a graduate of Syracuse University’s biomedical engineering program, designed a face shield that is now being produced by local manufacturer Tessy Plastics. The shield will be used by 30,000 medical professionals in Onondaga County. The Tessy R&D engineer worked at the College of Engineering and Computer Science (ECS) Student Shop, a space with 3D printers and computer numerical control machines where he had assisted workshop and project manager Tim Breen with student projects, and he used those skills to rapidly design, machine, assemble and test a prototype. “We’re so proud to see Brian’s contribution in the fight against COVID 19. This is a crisis where biomedical engineers are making a big difference, solving problems in the design and manufacturing of personal protective equipment, medical equipment, therapeutic interventions, and telemedicine,” says Julie M. Hasenwinkel, professor and chair of the biomedical and chemical engineering department at ECS. “I think this is a great example of how hands-on learning in ECS is preparing our students to be on the front lines, tackling the real-world engineering challenges of today and the future.” The project built upon a multi-disciplinary rapid response 3D initiative by VPA’s School of Design, the School of Architecture, and the College of Engineering and Computer Science. Read the full story by Brandon Dyer here.